Material Tech Sheet

Ho’okipa Ultra PE

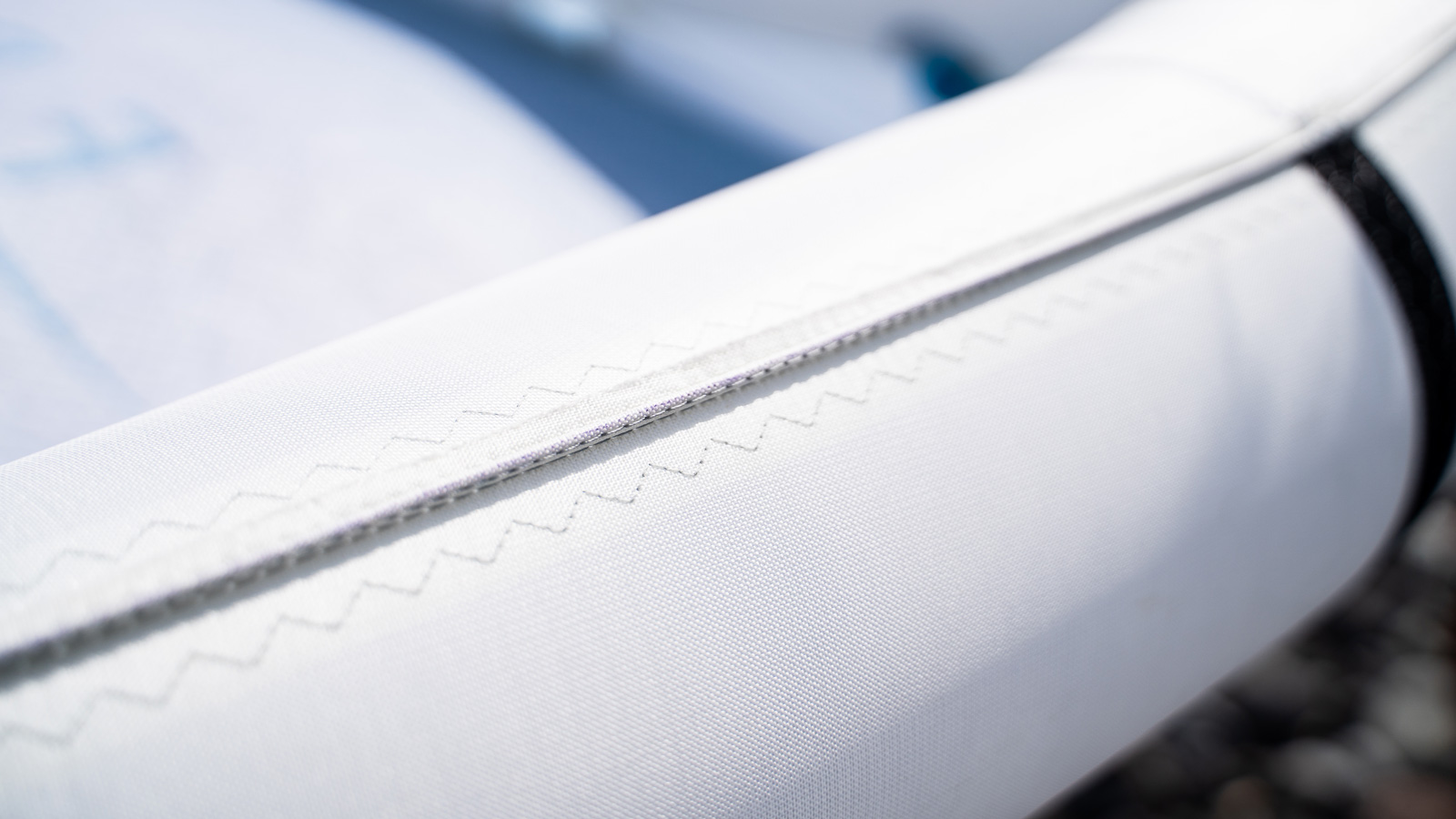

Airframe – Leading Edge & Strut

Weight: 120 GSM

Developed in conjunction with Challenge Sailcloth, this unique woven composite is the result of exhaustive development and testing, to find the optimum balance between responsiveness, lightweight and long-term performance.

Traditional Ultra PE materials relied on a high percentage of films, coatings or glues to stabilize the material. The outcome of this was that these materials were strong, but either needed complicated seam constructions, had a limited amount of structural ber (for their given weight) or had inconsistent strength and distribution throughout the fabric.

Ho’okipa Ultra PE takes a reliable woven structure and supercharges the material through the use of Ultra PE instead of traditional polyester fabric.

The high amount of material in the composite that is structural, has allowed us to optimize all areas of the construction resulting in that beautiful blend of responsiveness, lightweight and durability.

Incredibly, this high-performance fabric we have developed, comes with a reduced environmental impact beacuse Ho’okipa Ultra PE is made up of 48% recycled content by weight.

Composition:

▸ Ultra PE Primary Woven Structure

▸ 0.25mm Laminated backing

Key Benefits:

▸ High-pressure loading

▸ Abrasion and cut resistance

▸ Ease of repair

Application: Leading Edge & Strut